Robots have different applications in different markets and come in many forms, including service robots, collaborative robots (cobots), industrial robots, autonomous drones and autonomous guided vehicles. One of the key factors for the success of robotic applications is to ensure optimal motor driver design. Silicon-based motor drives require a compromise between efficiency and size. For example, higher switching frequencies enable smaller passive components, but lead to increased heat dissipation due to considerable switching losses. It has been suggested that this compromise could be overcome by replacing silicon switches with gallium nitride (GaN) high electron mobility transistors (HEMTs). This paper investigates whether this is true for GAN-based motor drivers.

Structure and design of GAN-based motor driver

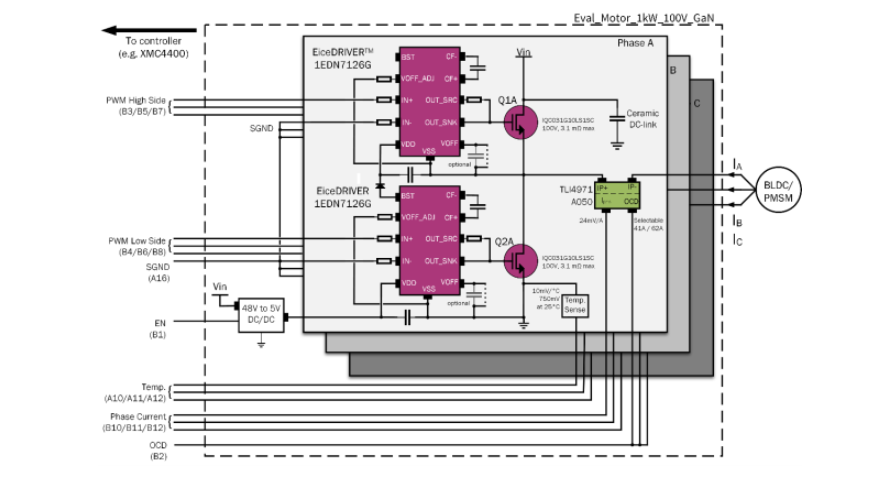

Figure 1 shows the top-level block diagram of a 100V GAN-based motor driver. The design centers on a half-bridge circuit of two 100V, 3mΩ CoolGaN Schottky gate HEMTs, each with an exposed bare piece at the top of the package for double-sided cooling. The half-bridge circuit has the smallest loop inductance (400pH) and enables very fast voltage conversion in the 1ns range without exceeding the peak drain voltage rating.

Figure 1: Motor driver for a 100V GAN-based CoolGaN Schottky gate HEMT

The gate driver chosen for this design is the 1EDN7126G, a member of the 1EDN71x6G EiceDRIVER gate driver family, designed for use with GaN switches and logic level MOSFETs. Flexible switching speeds for different pull/fill current intensities ranging from 0.5A(1EDN7146G) to 2A(1EDN7116G). At the same time, layout complexity and loop inductance are reduced compared to designs with isolated gate resistors.

True differential Input (TDI) is a feature of the series, ensuring stable operation even during fast switching transients. It provides common-mode voltage suppression for the high-voltage side switch and ground rebound immunity for the low-voltage side. In addition, the 1EDN71x6G series also features an "Active Miller clamp" (AMC) at the output stage, which increases its pull-down strength to 5A in less than 3ns after the gate voltage drops below 0.4V. This allows the turn-off speed of GaN HEMTs to be changed without increasing their immunity to inductive conduction sensitivity. The 0.3Ω underpull resistance means that once the driver is latched, the gate voltage is safely maintained at 0V, even when switching at high speeds.

Three half-bridges include separate temperature and in-phase current detection. Thin 100V ceramics are used on both sides of the board, ensuring a total DC link capacitance of more than 80µF. The high switching frequency reduces the ripple current on these capacitors, which in turn eliminates the need to use large electrolytic capacitors.

The design uses a 48V to 5V buck DC/DC converter to provide a stable supply voltage to the low-side gate driver. The 1EDN71x6G EiceDRIVER has a lift clamp function for powering high-side gate drivers.

The in-phase current detection is superior to traditional low-side current measurement to optimize the inductance of the high-frequency power supply loop and take advantage of the fast switching speed provided by the CoolGaN HEMT. Isolated in-phase current sensors have better voltage transient immunity than differential current amplifiers. The XENSIV TLI4971 meets these requirements with a coreless design based on monolithic Hall technology, providing a very linear output and a configurable sensing range from ±25 to ±120A. The 240kHz bandwidth is available even for demanding field-oriented control (FOC) applications.

The XMC4400 driver card offers a sensorless FOC with a maximum switching frequency of 100kHz and an updated control loop of 20kHz. Increasing the control frequency to the same as the switching frequency allows for higher control bandwidth in applications that require fast dynamic control responses.

The top view, side view, and upward view of the motor driver design are shown in Figure 2. All components of the entire motor driver, including DC link capacitors, current sensors, auxiliary power supplies and convenient test points, are located in a rectangular area of only 56mm x 40mm. The board is only 3.7mm thick. As a result, the total volume of the solution is 8.3cm³, which means that the motor driver has a power density of 120W/cm³, or 2kW/in³, in applications that require 1kW of power processing capacity.

Figure 2: Top view, side view and elevation view of the CoolGaN motor drive

Two factors that limit the voltage change rate of a motor are winding insulation breakdown and bearing wear. Winding insulation is not a significant issue for 48V motors (typically with higher voltage level insulation ratings). Bearing wear can be a problem in some 48V motors, so the switching speed of motor drivers is sometimes limited for these reasons. However, the cable connecting the driver to the motor significantly affects the effective dV/dt on the motor side, as shown in Figure 3. In this study, the dV/dt on the motor is approximately one order of magnitude lower than that seen at the CoolGaN motor driver (4.9V/ns versus 51V/ns). In addition, application-specific factors such as mechanical load, nominal speed and temperature must be considered to determine bearing life.

Figure 3: Comparison of switch waveforms, directly at the switch node with a tight probe loop (blue), at the slightly extended probe loop at the screw terminal (red), and directly at the motor terminal between the two phases measured using the optically isolated differential probe (green and orange)

Higher switching frequency improves system efficiency

The high-speed switching of CoolGaN devices gives designers greater choice in choosing switching frequencies. It allows them to consider end-to-end efficiency and overall solution size, rather than just focusing on inverter efficiency.

The system efficiency of this CoolGAN-based motor driver was measured in conjunction with commercial low-inductance (20µH phase) high-pole number (14P) drone motors at 20, 60 and 100kHz switching frequencies. A multimeter is used to measure the DC input power of the inverter, and a dynamometer is used to measure the mechanical output power of the motor. For comparison, Figure 4 shows the phase current waveforms operating at 100W and 500W at 20kHz and 100kHz. Higher switching frequencies significantly reduce current ripple, RMS current, and heating. At 100W, the RMS current is reduced from 5.6A to 4.5A(20% reduction); At 500W, it decreases from 26.2A to 23.1A(12% reduction).

Figure 4: Phase current waveforms for 100W(left) and 500W(right) operation

Although the relative reduction of RMS phase current at higher switching frequencies is more pronounced at light loads, the advantage in winding temperature can be seen across the load range. At 500W mechanical output power, the winding temperature drops from 110˚C at 20kHz to about 80˚C at 100kHz (Figure 5). This is important for applications such as collaborative robots where heat dissipation is a consideration.

Figure 5: Motor winding temperature at 20, 60, and 100kHz operation

A lower current ripple in the motor reduces winding and core losses, thereby reducing the motor temperature. However, the switching loss is proportional to the switching frequency, thus increasing the power loss and temperature of the inverter. For traditional MOSFETs or IGBt-based designs, this would be an unfavorable compromise due to high switching losses. However, because the CoolGaN HEMT has extremely low switching losses, end-to-end efficiency improves with increasing switching frequency, as shown in Figure 6.

Figure 6: End-to-end efficiency at 20 and 60 KHZ

Conclusion

This paper introduces the design of GAN-based motor driver for 48V applications using sensorless FOC scheme.

Design evaluations show that GaN devices are capable of using higher switching frequencies without reducing system efficiency or temperature limitations. These higher frequencies result in lower motor temperatures, higher end-to-end system efficiency, and higher power density. Its smaller form factor means that the motor driver can be embedded near the motor chassis (for example, inside a robotic arm), mitigating EMI caused by long connector cables.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.