InnovationLab now offers BaMoS for automotive applications with its innovative Battery Monitoring solution (BMS). It uses ultra-thin print pressure and temperature sensors that capture detailed battery data to each battery level, extending battery life by 40 percent.

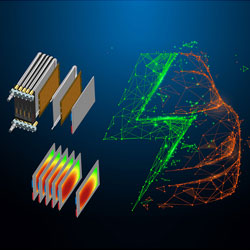

With BaMoS, the company provides a system that monitors this "breathing" to measure charging status, detect any abnormal behavior and eliminate overcharging as the cell expands and contracts throughout the charge-discharge cycle. The system captures detailed battery-level pressure and temperature data from ultra-thin printed sensor foils placed between individual cell cells.

This battery-level information parses the data spatially and temporally to provide an accurate picture of battery behavior. And provides valuable insights into health and performance states, helping the r&d team improve its battery design and battery monitoring solutions -- including expanding the range of electric vehicles.

Luat Nguyen, Managing Director, InnovationLab said:"Measurement is the first step in improving control and battery performance," "Our flexible, ultra-thin printed sensors provide detailed, accurate data that is necessary to improve the performance and life of electric vehicle batteries."

InnovationLab offers a complete battery monitoring solution, including sensor foils, electronics to collect and process captured data, and software to visualize, store and analyze data in real time. Both pressure and temperature sensors are customizable in size, resolution and substrate material to your specific requirements.